All about 24??media

All about 24??media

Blog Article

Not known Details About 24??media

Table of ContentsFascination About 24??mediaSome Known Details About 24??media Some Of 24??media24??media - TruthsThe Basic Principles Of 24??media

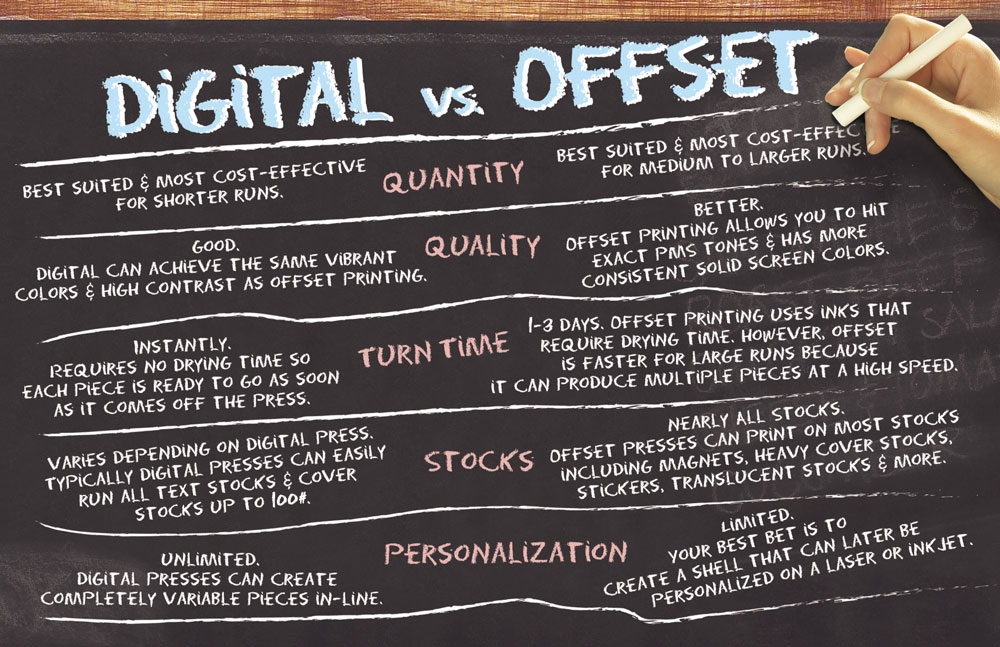

Advancements in print technology are changing the communications playing field when it involves top quality, affordability and innovative capabilities. Balanced out printing and electronic printing are the significant procedures by which print work are taken on both making use of four-color printing techniques. Each option has its benefits, offering different techniques to satisfy the needs of diverse production projects.

Commonly, this has been the most constant strategy for specifically maintaining shade suits, making it perfect for print runs that just call for static printing such as pre-printed kinds, sales brochures, leaflets, organization cards, and mass postcard mailings. Due to the static nature of litho printing, it is not optimal for variable print items that will certainly be mailed to private recipients such as declarations, letters, and individualized postcards.

A Biased View of 24??media

The most up to date developments in print technology are assisting to bring several of offset's benefits into the electronic printing world truly transforming the face of modern printing! There are some vital differences between Offset Printing and Digital Printing (Window Vinyl). This guide reveals the benefits and drawbacks of each printing method. There is an indisputable and expanding number of advantages to utilizing the digital print procedure.

Today's electronic print equipment is amongst the most innovative on the marketplace. Here are some of the most significant benefits of making use of digital printing: dominate the digital print space, with full-color printing completed in one process and effortlessly published straight from a print data. Without an extensive set up procedure, the calibration time of a specific job is reduced, adding to quicker print time and overall shipment.

The inkjet printing process has helped to change the sector along with the quality and speed of the result. The most recent inkjet modern technology can print on conventional countered supplies with boring, silk, and shiny surfaces. High-quality digital print paired with software-managed color monitoring practices includes optimum value to publish items and makes production procedures extra reputable than countered.

The Definitive Guide for 24??media

(https://www.avitop.com/cs/members/za24media.aspx)

Environmentally friendly and biodegradable inks and toners are additionally available for more sustainable printing. Digital print likewise gets rid of the demand to wash plates or coverings with damaging chemicals at the end of the printing process.

Variable information aids organizations reach their exact clients and target market with uniquely-created and customized material. As modern technology improves, the top quality of electronic printing has actually come to be second-to-none, with greater information, color match capabilities and total precision. Without the demand to wash plates or utilize excess ink, digital printing is likewise much less wasteful and generally more environmentally pleasant.

("flexo"), include multiple make-ready steps to transfer an initial image to a substratum.

The Buzz on 24??media

While electronic printing is a practical alternative for many short-run print jobsunique events, prototyping, or various other considerationsits modern capacities truly receive quick turn-arounds. Being able to tailor packaging with variable information printing has opened brand-new possibilities for you to engage with your clients in even more customized ways. Digital printing, with fewer relocating items, is a lot more agile than offset in this regard.

Decreased set-up time saves cash on the front end. And given that these are not massive bulk orders, smaller sized companies can pay for to print without having to fulfill the greater and more pricey print limits of traditional printing.

Make certain you collaborate with a printing and product packaging partner that has the right certifications. While eleventh-hour printing and customization are a huge benefit, digital might not constantly be the very best method for you. Counter printing has the benefit of cost-effectiveness with huge print runs, particularly those with sophisticated ornamental effects and specialized coverings.

24??media Fundamentals Explained

Lithographic presses utilize two print platesa positive and a negativeto transfer high-grade color graphics onto an appropriate substrate. The favorable plate, with its smooth surface area, attracts oil-based inks and drives away water. On the other hand, the negative plate, with its rough structure, absorbs water and pushes back oil. Rubber rollers are then utilized to move the picture from the plate to the corrugated surface area.

Corrugated paper can often prove to be a tough surface to publish on, but Litho prints to a separate surface and is then laminated to it, making it easy to publish high-quality photos. It can be incredibly consistent, also for futures. Actually, the much more you publish, the less expensive the expenses end up being for Litho.

If you have sufficient time and budget plan, and a big volume of a solitary layout, then there should not be a problem. What Litho does not give you is specifically what Digital does, personalization. Extra on that later. Expensive established Longer turnaround No Variable Data Printing Smaller shade gamut, colors can be less brilliant Digital printing is the process of printing electronic photos straight onto the corrugated substratum utilizing a single-pass, direct-to-corrugate strategy - Stickers.

Report this page